Our Injection Molding Process

Tell Us What You Need

Send us your part drawing, prototype, or design idea. We’ll review and provide a detailed quote for tooling and production.

Design Review

Together with our mold-building partners, we will assess the part for moldability and make any improvements needed to ensure reliable performance.

Sample Production

We’ll build your mold and produce initial T-1 samples. Once approved, we finalize the mold with polish and texturing.

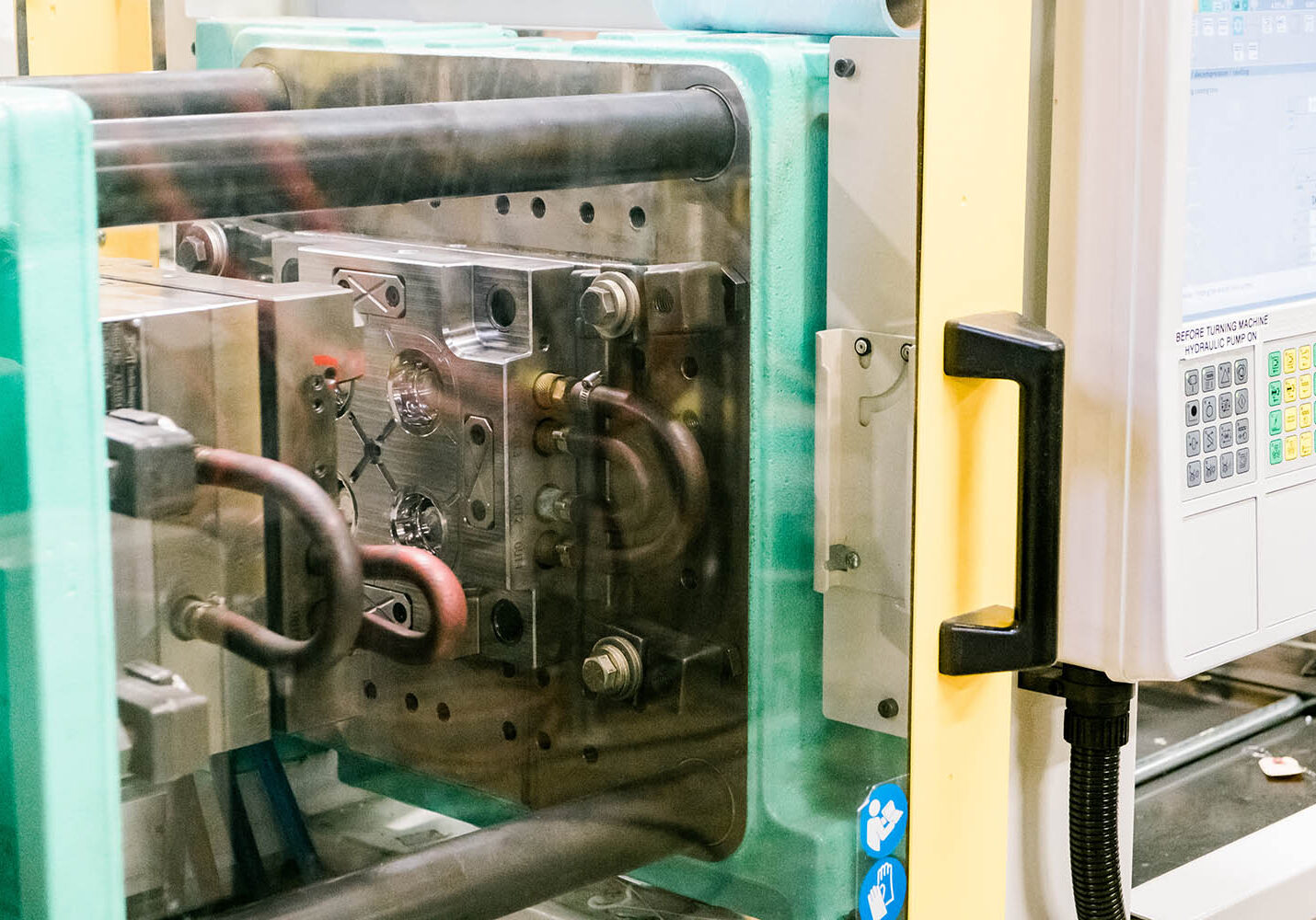

Full Production

We inspect, prep, and run your mold in our facility. After a final sample check, we begin full-scale production.

Make Tamarack Your Injection Molding Partner in California

Ready to work with a reliable, U.S.-based injection molding company that serves all of California? Tamarack Industries offers custom plastic manufacturing with faster delivery, no minimums, and unmatched support.

Why Work with Tamarack for Injection Molding in California?

Custom Plastic Injection Molding

We work with new product designs or existing molds to produce durable, consistent parts. Whether you need 10 units or 10,000, we’ll help you get the right results with no minimum order.

Full-Service Capabilities

Beyond injection molding, we also offer:

- Part design and prototyping

- Mold design and testing

- Secondary operations such as assembly, welding, and drilling

Flexible Mold Sizes and Shot Capacity

Our presses range from 25 to 500+ tons, with shot capacities from 1 to 2,267 grams—allowing us to create everything from tiny components to larger-format parts.

Quality Compliance

Tamarack Industries ensures that all products meet or exceed applicable internal and external quality standards and are free from workmanship-related defects.

Industries We Serve in California

Manufacturing & Shipping Supplies

Core plugs, roll cradles, protective caps

Agriculture & Food Production

Parts for harvesting, irrigation, and food safety equipment

Industrial & Heavy Machinery

Components for OEMs and replacement parts

Sporting Goods

Durable plastic parts for outdoor and performance equipment

And More

We can manufacture custom-molded parts for almost any industry.

Injection Molding Pricing Factors

Our pricing depends on several factors:

- Quantity – Larger runs usually offer better per-unit pricing

- Complexity – Intricate parts tend to be more costly than less intricate parts

- Part Size – Smaller parts typically cost less due to shorter cycle times

- Material Selection – We offer ABS, nylon, HDPE, PP, acetyl, and other thermoplastics

Contact us for a quote based on your part design and quantity.

Our Service Areas

Tamarack Industries is available to serve businesses throughout California, including:

- Sacramento

- San Jose

- Oakland

- Modesto

- Stockton

- Santa Rosa

- Napa

- Redding

- Chico

- Fairfield

Frequently Asked Questions

We work with a variety of materials, including HDPE, polypropylene, ABS, nylon, and acetyl, with options for recycled content.