Our Injection Molding Process

Tell Us What You Need

Bring us your part drawing, CAD file, or prototype idea. We’ll review and prepare a quote for tooling and production.

Design Review

Our team and tooling partners evaluate your design for moldability. We’ll suggest refinements that improve consistency and reduce production issues.

Sample Production

We build the mold and run the first T-1 samples. Once you approve, we finish the tool with texturing, polish, and adjustments.

Full Production

After inspection and testing, we move into full production, ensuring your parts meet quality and performance expectations.

Make Tamarack Your Injection Molding Partner in Oregon

Looking for a dependable Northwest injection molder? Tamarack Industries provides durable plastic parts with flexible volumes, quick response times, and personal support.

Why Work with Tamarack for Injection Molding?

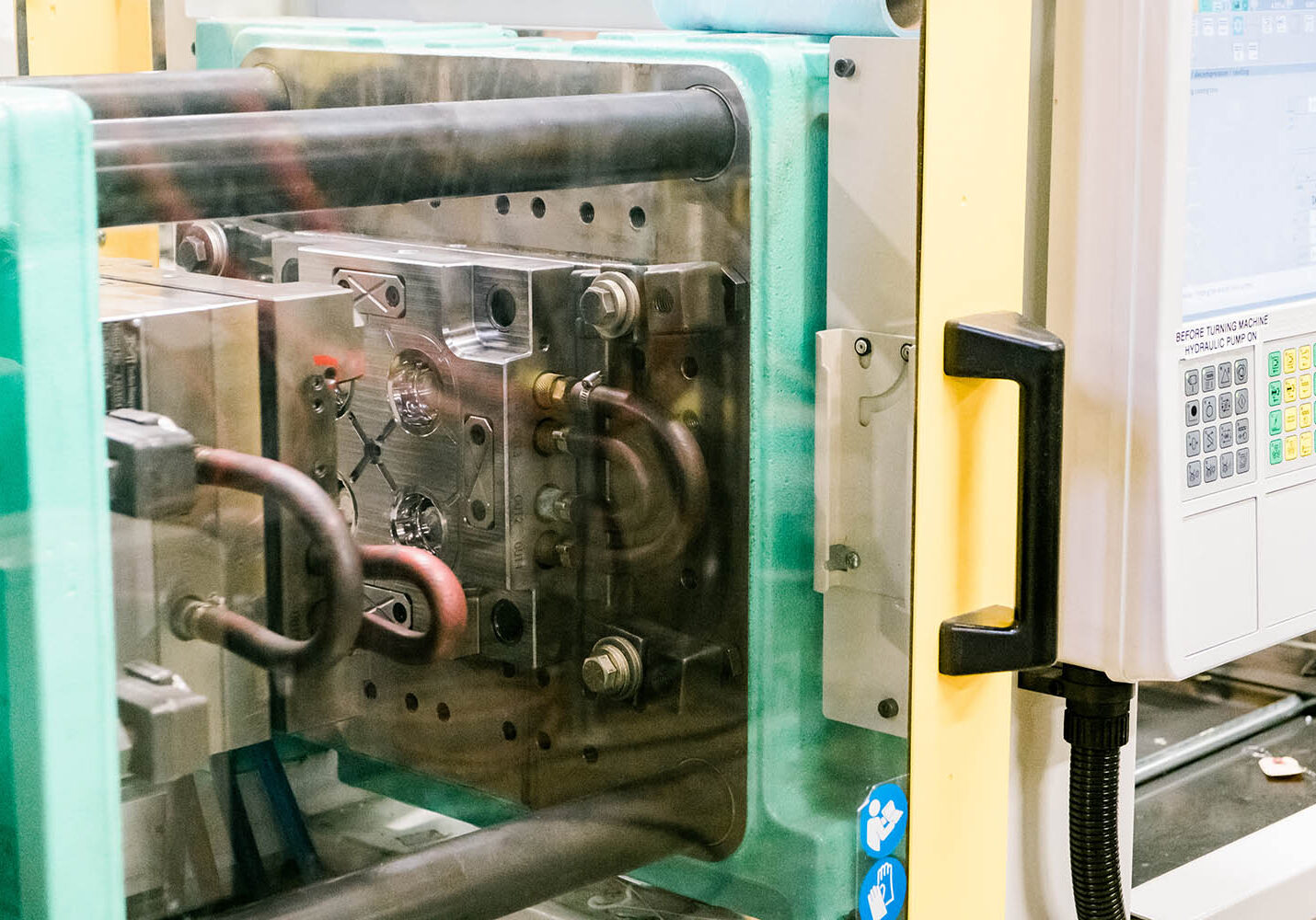

Custom Plastic Injection Molding

We can produce brand-new parts from concept or run existing molds. Whether you need a handful of prototypes or a large production order, we can deliver.

Full-Service Capabilities

Our services go beyond molding to include:

- Part prototyping and design input

- Tooling and mold development

- Post-molding processes such as assembly, trimming, and welding

Flexible Mold Sizes and Shot Capacity

Our machines run from 25 to 500+ tons with shot capacities ranging from 1 gram to over 2,200 grams. This allows us to handle both delicate components and larger structural parts.

Industries We Serve in Oregon

Packaging & Logistics

Core plugs, roll cradles, protective end caps

Agriculture & Food Handling

Components for irrigation systems, harvesting, and processing equipment

Heavy Equipment & Industrial

Plastic parts for OEMs and aftermarket applications

Outdoor & Recreational Products

Strong, lightweight parts for sports and performance gear

Other Applications

We support many industries outside of regulated categories like aerospace or medical devices

How Much Does Injection Molding in Oregon Cost?

Several factors determine project pricing:

- Order Volume – Higher runs lower the per-unit cost

- Part Complexity – Detailed designs require more tooling time

- Part Dimensions – Smaller items generally run faster and cost less

- Material Choice – We mold in ABS, nylon, HDPE, polypropylene, acetyl, and more

Request a quote and we’ll outline costs based on your design.

Our Service Areas

We work with companies throughout the state, including:

- Portland

- Eugene

- Salem

- Bend

- Beaverton

- Hillsboro

- Medford

- Corvallis

- Springfield

- Ashland

Frequently Asked Questions

We work with ABS, nylon, HDPE, PP, acetyl, and other thermoplastics. Recycled options are also available.