Our Injection Molding Process

Tell Us What You Need

Share your drawings, CAD files, or prototype ideas. We’ll review and provide a detailed quote for tooling and production.

Design Review

We evaluate your part for moldability and suggest refinements that improve strength, function, and cost-efficiency.

Sample Production

We manufacture your mold and produce first-run samples (T-1). Once approved, we complete finishing work like texturing or polishing.

Full Production

Your mold is tested, prepped, and run in our facility. After a final inspection, we move to full-scale production and ship directly to your Seattle location.

Let’s Get Started

Looking for a regional injection molding partner with reliable turnaround and responsive support? Tamarack Industries provides custom plastic parts that meet your needs—on time and with no minimum order requirement.

Why Work with Tamarack for Injection Molding in Portland?

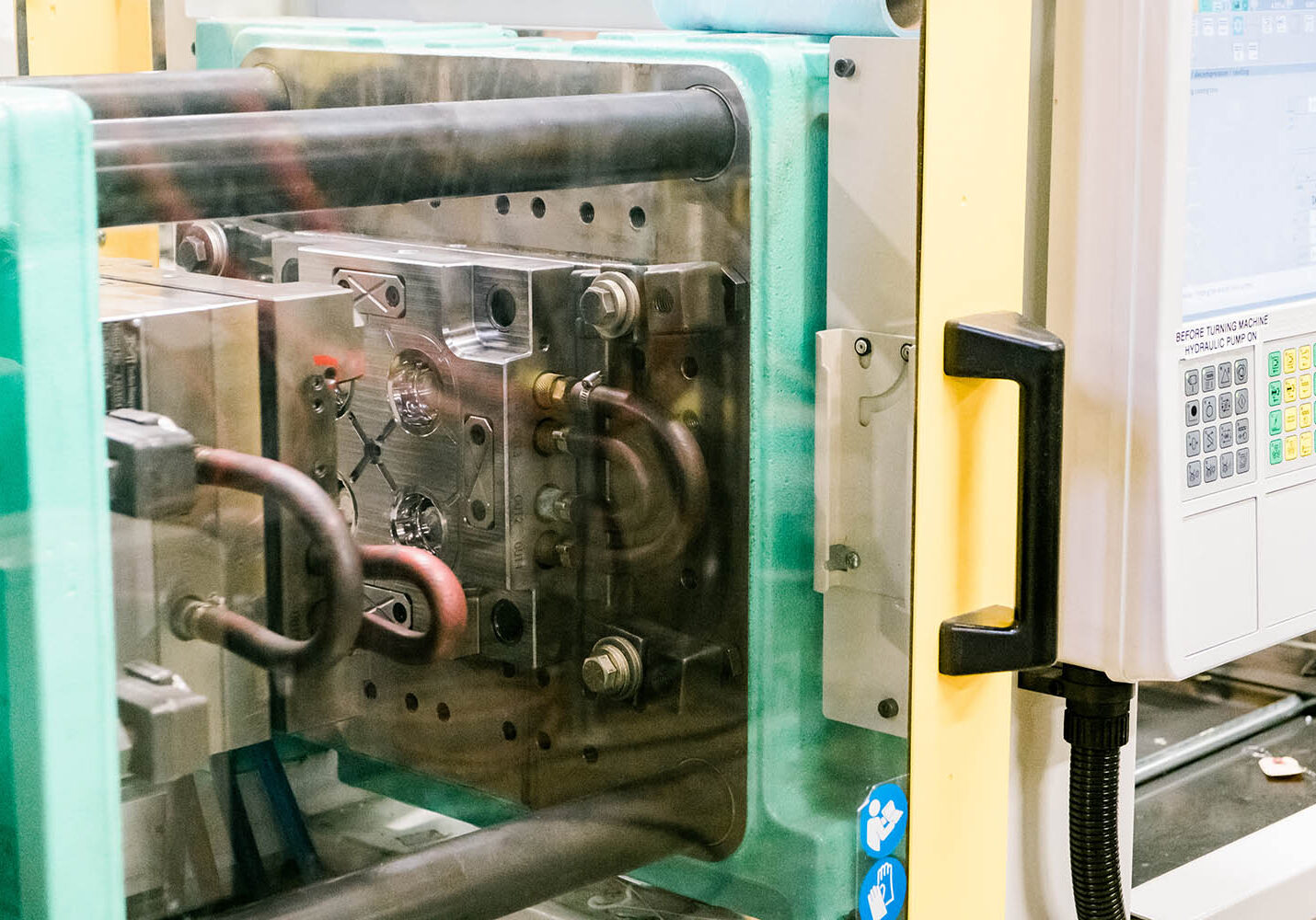

Custom Plastic Injection Molding

From prototypes to production runs, we create reliable, repeatable parts—whether you need a handful or thousands.

Full-Service Capabilities

We provide more than molding, including:

- Prototyping and design support

- Mold design and validation

- Secondary services such as trimming, assembly, and welding

Flexible Mold Sizes and Shot Capacity

Our presses cover 25 to 500+ tons with shot sizes from 1 gram up to over 2,200 grams, allowing us to mold small precision components and larger industrial parts.

Industries We Serve in Portland

Technology & Electronics

Components for devices, housings, and accessories

Food & Beverage

Plastic parts for packaging and food-handling equipment

Industrial Manufacturing

OEM and replacement parts for machinery

Outdoor & Recreation

Durable components for performance gear and sporting good

Logistics & Packaging

Core plugs, roll cradles, and protective shipping parts

How Much Does Injection Molding in Seattle Cost?

Your project cost depends on:

- Order Size – Larger runs reduce per-unit costs

- Complexity – More detailed parts require additional tooling and setup

- Dimensions – Smaller parts run faster and cost less per unit

- Material Selection – Options include ABS, nylon, HDPE, polypropylene, acetyl, and more

Request a quote for pricing specific to your part design and quantity.

Frequently Asked Questions

We work with ABS, nylon, HDPE, polypropylene, acetyl, and more—with recycled options available.