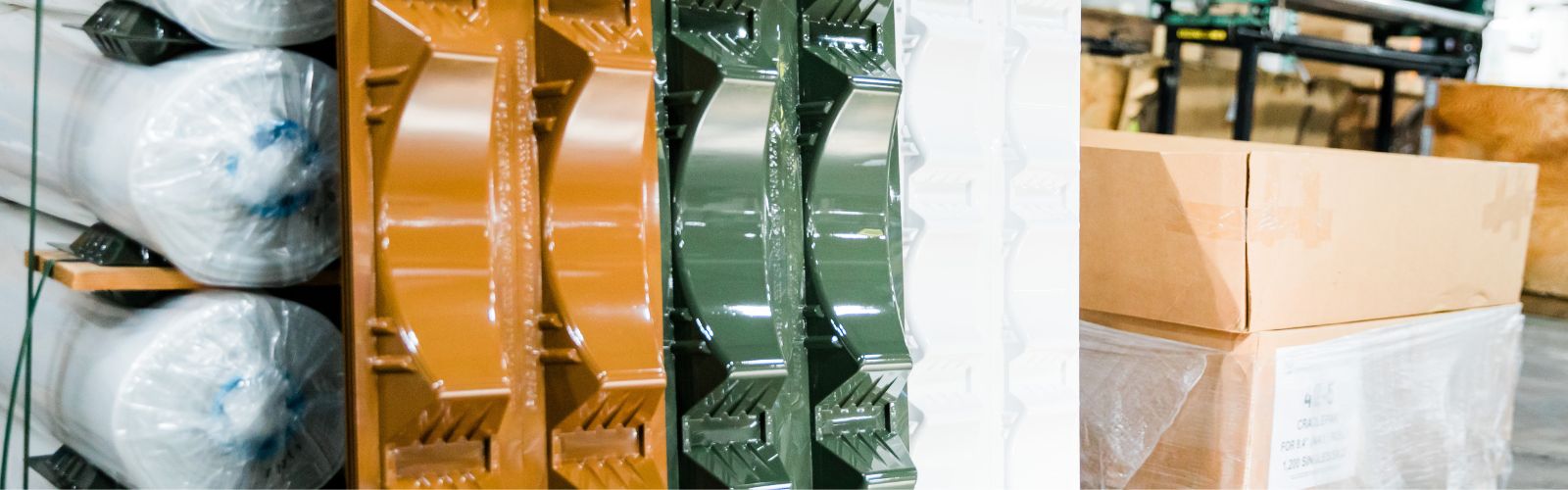

Roll cradles are an essential tool for shipping and storing rolls of plastic, paper, textiles, and other materials. There are several different types of cradle packaging available, but plastic roll cradles remain the top choice for a host of reasons.

CradlePak: Plastic Roll Cradles from Tamarack

Tamarack’s plastic roll cradles provide a strong, durable, and affordable solution for the protection of your materials. The thermoformed design of CradlePak offers the most compact nesting in the market. A stack of 2,400 CradlePaks takes up a similar amount of space as 360 pulp cradles. Not only does this help your business maximize storage space, but also keeps your production floor clear of clutter and improves safety.

The Benefits of Plastic Roll Cradles

Durability

Plastic roll cradles are engineered for strength and resilience—they’re capable of withstanding the rigors of transportation and heavy use without compromising the protection of the rolls. This durability reduces the risk of damage during transit, which saves companies on potential losses and replacement costs.

Affordability

Compared to other storage and transportation solutions, plastic roll cradles offer a cost-effective alternative. However, their affordability does not compromise quality or performance.

Sustainability

When you buy plastic roll cradles from a company like Tamarack, you’re buying with sustainability in mind. Our cradles are made from recycling Code 1 PET plastic, and they can be recycled in turn — which helps you reduce your carbon footprint. It is also possible to reuse them, which reduces the need to buy new cradles more often, further improving their sustainability.

Cleanliness

Plastic roll cradles are clean and resistant to moisture. This allows them to be continuously reused and it creates an optimal presentation for your materials, whether they’re on the plant floor or arriving at your customer’s facility.

Efficiency

With features designed to simplify handling and storage, plastic roll cradles can help improve your operational efficiency. Their compact, stackable design and ease of use can reduce labor requirements and maximize storage space to increase your overall productivity.

More Shipping Products from Tamarack

Core Plugs

If you’re looking for roll cradles, then you might need core plugs as well. Tamarack’s plastic core plugs are highly durable and crush resistant. They are also fully customizable, including their color, material, size, and more. And just like our roll cradles, our core plugs are made from recycled plastic and can be recycled in turn.

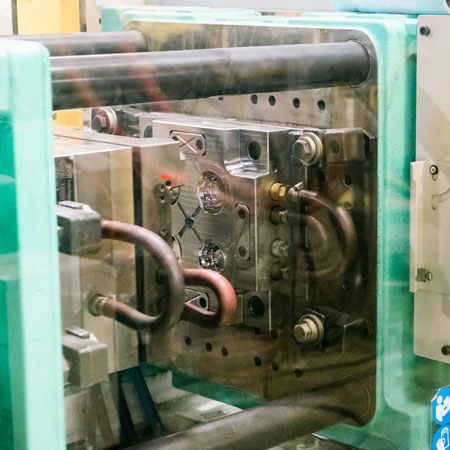

Plastic Injection Molding

If you’re looking for custom shipping, storage, and other solutions, Tamarack offers affordable and bespoke plastic injection molding.

Our presses have a clamping force ranging from 25 to more than 500 tons, so we can cover a range of different mold shapes and sizes with high-quality results. Our equipment also has a wide-ranging shot capacity, with anywhere between 1 gram to 2,267 grams of material that we can use to fill the mold.

When you work with us to make your custom injection molded part, we can help with total part design services from start to finish. Each phase of the mold production process—from part and mold design to development and manufacturing—is handled at our headquarters in Yakima, WA, for a faster and more efficient workflow.

Our team of experts is also happy to help with related secondary operations for injection molding, including ultrasonic welding, drilling, and assembling for your custom molding needs.

Order Plastic Roll Cradles Today

Looking for affordable cradle packaging for your material storage and shipping needs? Reach out to the team at Tamarack for a quote on CradlePak.