Core plugs play a key role in keeping your products secure and presentable during transportation. But what type of core plug is right for your needs? We’ll walk you through the various types of core plugs and where they work best so you can feel confident in your purchase.

How Core Plugs Protect Your Materials

Core plugs are essential for protecting the core that materials are wound on, such as paper, film, foil, and textiles. They help maintain the roll’s shape, prevent damage during handling and transport, and can even support suspension for storage. By evenly distributing pressure and providing structural support, core plugs prevent deformation and facilitate easier, more efficient handling of rolls.

Why Choose Plastic Core Plugs?

Plastic core plugs are increasingly becoming the material of choice over alternatives like wood or metal. Their lightweight nature reduces shipping costs, and their inherent resistance to moisture ensures durability and longevity. Furthermore, plastic core plugs offer a versatility unmatched by other materials. They can be engineered to fit any size or specification and their recyclability also aligns with modern sustainability efforts, making them a responsible choice for businesses.

What Are the Different Types of Core Plugs?

Single Plugs

Single plugs are the most basic core plug design. They are great for light rolls or when rolls are stored flat. They are simple yet effective in preventing core collapse and maintaining roll integrity.

Double Plugs

Double core plugs are made to enable manufacturers to stack their rolls vertically on pallets. Vertical stacking allows for faster efficiency of loading and unloading rolls, while maintaining stability.

Pad Plugs

Pad plugs are a versatile solution that combines the benefits of core and edge protection. They are particularly effective for sensitive materials that need extra care, as they suspend material inside individual boxes. They are popular with rolls of material that include print media and graphics, or that are otherwise delicate.

Roll Suspension Plugs

Roll suspension plugs are designed for systems where rolls are suspended during storage or transport. This design minimizes contact with the roll’s surface, reducing the risk of damage and making them ideal for high-value or delicate materials. The longer length and larger flange of roll suspension plugs, paired with end boards or inserts, helps protect and secure your products.

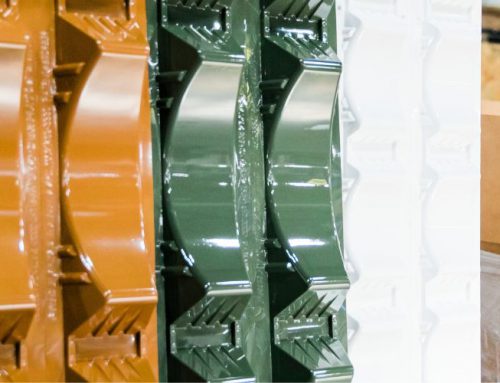

Core Plugs from Tamarack

Tamarack Industries is proud to offer a comprehensive range of core plugs designed to meet the diverse needs of our customers. Our products embody the benefits of plastic core plugs, with durability, versatility, and sustainability at the forefront. They’re made from recycled materials, and they can be recycled again in turn after use.

Whether you need single, double, pad, or roll suspension plugs, Tamarack has the solution for you. We have sizes ranging from 2 to 12 inches in diameter, as well as different levels of durability, strength, and crush resistance. If we don’t already manufacture it, we have the capability to produce the custom solution you require.

Order Core Plugs Today

Ensure the protection and integrity of your materials with Tamarack Industries’ core plugs. Our commitment to quality, innovation, and customer satisfaction makes us the preferred plastic core plug manufacturer.

Contact us today to find the perfect core plug solution for your needs.