Choosing a plastic injection molding company to work with is a significant step in creating high-quality products at the production capacity that you need. However, there are plenty of injection molding manufacturers to choose from, which is why it’s important to know the right questions to ask and the right things to look for when making a decision.

What Makes a Good Plastic Injection Molding Company?

Experience

One of the first aspects to consider when looking for a plastic injection molding manufacturer is their level of experience. Companies with a proven track record of working with complex designs in a wide range of industries can help save you time and money. You can trust the timelines that they give you and the recommendations that they make.

It’s always a good idea to check out a company’s website to see how long they’ve been in business, the range of services they offer, and the type of companies that they’ve worked with.

When you reach out to a prospective plastic injection molding company, ask them if they have experience working with the type of product that you need. The company may also be able to tell you about current and previous clients they’ve worked with, even if they can’t always give out specific names due to confidentiality.

Plastic injection molding companies that have a lot of experience in the industry are also likely to have built strong relationships with their partners, such as their mold manufacturers.

Expertise

Working with a company that knows what they’re doing will always make for a great experience. Before you start working with an injection molding manufacturer, it’s a good idea to have an extensive conversation with the team about their process. They can walk you through step-by-step how they work with their clients and trusted partners to ensure a great final product. This is a great opportunity to ask them how they review designs and what quality assurance checks are used.

Plastic injection molding companies with a lot of expertise can also help you find ways to save money by ensuring a smooth and efficient process and using the best materials for the job.

Affordability

Everybody loves a good deal, but it also pays to dig deep into the numbers. The lowest bidder won’t always be the best option if they are offering less durable materials or imprecise molds. Plus, your business stands to lose plenty of money if there are defects in the product or if production falls behind and creates a bottleneck in your process.

One of the best ways to find a plastic injection molding manufacturer that will be cost-effective is to look for a local company. Not only is it great to work with local businesses, but it will also allow you to cut down on shipping costs.

It’s important to do your research and feel confident that the option you’re choosing is going to be a good deal now—and a year down the road.

Communication

Working with a plastic injection molding company that is able to build great relationships with its customers based on trust and transparency is an invaluable asset. Smaller companies are often able to build direct, personal relationships with their customers that you might not find at a larger manufacturer.

Make sure you’re able to talk directly with the person who will be your point of contact at the company. See that you can trust what they say and that they’ll always make sure that you have all of the information that you need.

Capacity

The production capacity of a plastic injection molding company is a critical factor in terms of how well it can serve your needs. There are two types of capacity that this can refer to, the shot capacity that determines the size of the products they can create, and their overall production capacity that determines how many products they can produce for you—and how fast.

A wide-ranging shot capacity is helpful for ensuring that the injection molding manufacturer can take on projects of different sizes. It also means they could create multiple different types of products for your project.

Working with a large plastic injection molding company may mean that they have the ability to take on multiple projects without creating a bottleneck. But it may also mean that they prioritize larger projects over your own, so you’ll want to find one that won’t leave your project at the bottom of their to-do list.

Looking for a Good Plastic Injection Molding Company Near You?

Tamarack Industries is a plastic injection molding company located in Yakima, Washington. For more than 20 years, we’ve been providing high-quality, custom injection molding to a wide range of industries.

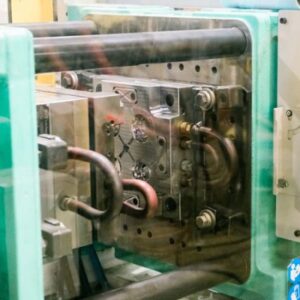

Our team can handle intricate and complex designs that use between 1 gram and 2,267 grams of material. Our molding presses have between 25 and 500 tons of clamping force, which allows us to work with a wide range of different mold shapes and sizes.

Plus, when you work with Tamarack to create a custom mold, our team will help with total part design services from start to finish. Each part of the mold production process is handled under one roof, which makes the process as seamless as possible and saves your team time.

The experienced staff at Tamarack is also able to help with secondary operations, such as ultrasonic welding, drilling, and parts of assembly.

Tell Us About Your Project

Looking for an experienced and reputable plastic injection molding company to help with your project? Reach out to the team at Tamarack Industries and tell us about what you need.

Get the Custom Packaging Solutions You Need

Get in touch to discuss your needs, request a quote, and explore how our products, our custom capabilities, and our team can best serve you.