Our Thermoforming Process

Why Work with Tamarack for Thermoformed Packaging?

Custom Plastic Thermoforming

Whether you need trays, lids, blisters, clamshells, or custom containers, we’ll work with you to create packaging that protects, presents, and performs. No minimums required.

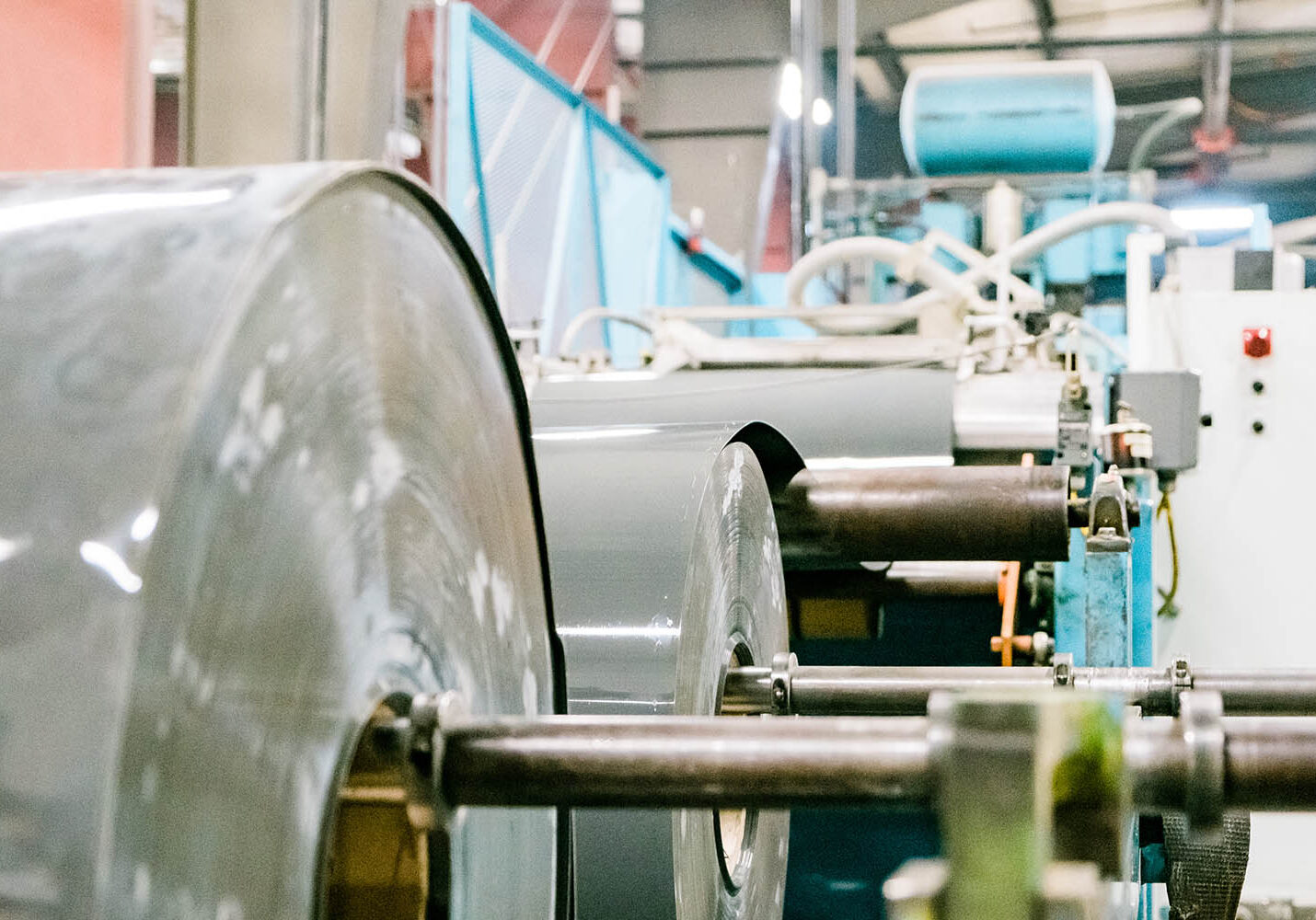

Roll-Fed Thermoforming with Form-Trim-Stack

Our roll-fed “form trim stack” process is ideal for high-efficiency packaging runs. We can produce custom pieces up to 30” x 48” using sheet plastic up to 0.060” thick.

Versatile Material Options

We work with a variety of sheet plastics, including but not limited to:

- RPET (recycled PET)

- PET

- HDPE

- Polypropylene (PP)

- PVC

- Styrene

Reliable, U.S.-Based Manufacturing

From mold design to shipping, all work is handled in our Yakima, WA facility using raw materials from trusted, long-term vendors.

Industries We Serve

Thermoformed Packaging Pricing Factors

The cost of your custom packaging depends on several factors:

- Mold Complexity: More cavities and custom features can affect cost

- Material Type: Each plastic has different price points and performance traits

- Part Weight and Size: Heavier or larger parts use more material and time

- Order Quantity: Higher quantities typically reduce your per-unit cost

We’re happy to review your specs and provide a clear, detailed estimate.

Order Custom Plastic Thermoforming for Your Business

Tamarack Industries provides thermoformed packaging to clients nationwide. We serve businesses across the U.S., including:

Make Tamarack Your Thermoforming Partner

Looking for dependable, custom thermoformed packaging made in the U.S.? Tamarack Industries delivers precision parts, fast lead times, and friendly, responsive service.

Frequently Asked Questions

We produce trays, lids, blisters, clamshells, inserts, and custom packaging in a wide variety of shapes and sizes.